The new onshore models have rotors 170 meters long | Siemens Gamesa

It’s a bloodbath in the wind industry.

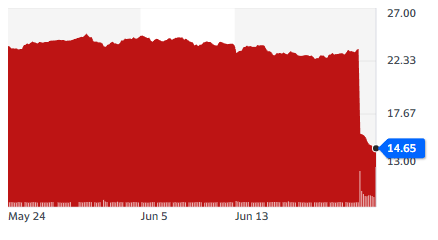

Despite the wind being free, collecting it appears to cost a fortune. Siemens Energy lost a third of its stock price on Friday. Just like that, seven billion dollars in market value disappeared.

Only a month ago they were expecting to break even, as the Wall Street Journal reports, the executives appear to have been blindsided by the rapidly escalating maintenance costs. The problem is so bad, and perhaps fundamental, that shareholders in other turbine manufacturers are selling out. Vestas Wind fell 7% Friday.

Siemens Energy Share Price, Yahoo Finance

The promise was that wind turbines would keep getting cheaper as they got bigger and better. Instead, issues are appearing now even in new installations, and people are starting to wonder if they’ve made the turbines too big too fast. The bearings and blades are wearing out, and the costs to fix them are crippling.

Clean Energy’s Latest Problem Is Creaky Wind Turbines

Carol Ryan, Wall Street Journal

Shares in Siemens Energy plunged by a third after it said turbine components are degrading faster than expected

The news isn’t just a blow for the company’s shareholders, but for all investors and policy makers betting on the rapid rollout of renewable power.

The creaky components, which affect 15% to 30% of the installed onshore fleet, will be expensive to fix. Management thinks the cost could run upward of €1 billion, equivalent to $1.09 billion, effectively wiping out more than a third of the profit the company is expected to make doing maintenance on wind turbines it has already installed, according to Bernstein analyst Nicholas Green.

These are not words CEO’s ever want to use: ” it’s much worse than even what I have thought possible”:

Siemens Energy Shares Plunge

Michelle Fitzpatrick, Barrons

In a call with reporters, Siemens Gamesa CEO Jochen Eickholt said “the quality problems go well beyond what had been known hitherto”.

“The result of the current review will be much worse than even what I would have thought possible,” he added.

In the call with reporters, Siemens Energy CEO Christian Bruch called the developments “bitter” and “a huge setback”.

The company has seen just “a handful of failures” across a fleet of several thousand turbines, he said, but it now had to assess “what to expect over the next 20 years” and which preventative measures to take.

To put it mildly – It’s either the rotor, the bearings “or the design” — could it be worse? It could — Siemens has already built 132 GW of wind plants — mostly onshore — and these new unforeseen problems may affect as many as 15 to 30% of their turbines. The maintenance costs to meet the warrantees they have already made are substantial. On top of that Siemens has “an order backlog of 34 billion euros”. This could be a very big hole…

Factbox: What are the issues with Siemens Gamesa’s wind turbines?

By Nina Chestney and Christoph Steitz, Reuters

On Friday, Siemens Gamesa said that while rotor blades and bearings were partly to blame for the turbine problems, it could not be ruled out that design issues also played a role. It said the problems could affect as many as 15-30% of its turbine fleet.

The company said quality problems “go beyond what we were previously aware of, and they are directly linked to selected components and a few, but important, suppliers”.

It’s a perfect storm of rising supply costs and unexpected maintenance costs:

The company was already being hit with issues such as the rising costs of steel and other key raw materials when the news of its wind turbine failures went public.

Chief executive, Christian Bruch has told reporters “Even though it should be clear to everyone, I would like to emphasise again how bitter this is for all of us”.

h/t to J.J and NetZeroWatch